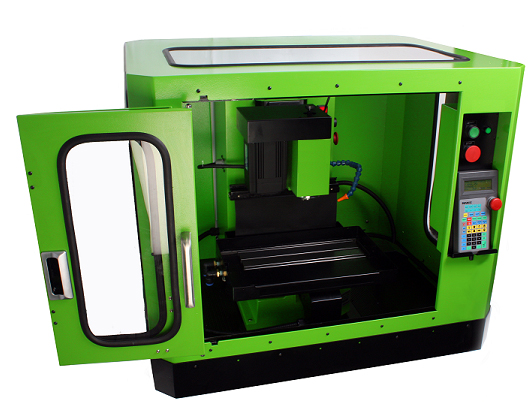

Máy cắt mẫu vật liệu TT-Cut II

Thiết bị kiểm tra và phân tích vật liệu

Model:TT-Cut II

Hãng sản xuất: Torontech

Xuất xứ: Mỹ

Test Specimen preparation is a difficult and time consuming operation. It is essential that the prepared specimen conforms to the required physical dimensions. In order to prepare high quality and accurate specimens, quality specimen preparation machines are required. ToronTech™ offers the ideal machine to meet these requirements.

The Sample Preparation Machine - TT-Cut II is cost effective in motion control application of up to 3 axes. The motion control of the Sample Preparation Machine - TT-Cut II is based on numerical control Technology. The Sample Preparation Machine - TT-Cut II adopts a simple connectivity and a single commercially available USB cable is used for communication between the PC and control board which can be placed as per user preference. In addition to the above the Sample Preparation Machine - TT-Cut II is equipped with additional features like:

Quick system setup:

PC-based NC board is easy to setup and can be placed beside the PC.

Easy to operate

SamCut II simple operating structures, makes PC-based NC easy to use, even for beginners.

Complex motion - Easy to program

The control system uses the PC-based NC, can be easily operated and it supports versatile file formats such as NC(G-code), PLT and DXF as input file formats.

Other functions of the Sample Preparation Machine - TT-Cut II

3D tool-path, 3D zoom-in and zoom-out allows close examination of the path profile and lock restart function reduces loss.

Application for the Sample Preparation Machine - TT-Cut II

- TT-Cut II-M: Ferrous & Non- Ferrous metals and Plastics

- TT-Cut II-T: Non- Ferrous metals, Steel, Titanium, steel alloys etc.

ControllerSpecifications of the Sample Preparation Machine - TT-Cut II

| DC Power inputs | 5V, 24V | ||

| Interface to PC | USB port | ||

| Interface Board | 3 Axes Pulse Distribution Board | ||

| Control Axes | 4 Axes Simultaneous Control | ||

| Input file format | PLT, DXF, NC, HPGL | ||

| Block restart | Just in case machining stops, restarting function is available for re-machining from the stopped point by using block count value. | ||

| 3D Machining from 2D Drawings | Repeat machining of each layer | ||

| Real time tool-path | 3D Viewing, Zoom in, Zoom out | ||

| Others | Manual jogging, Handle jogging Automatic return to machining start point Feed override, Feed rate Acceleration, Deceleration, etc. |

||

Technical Specifications of the Sample Preparation Machine - TT-Cut II

| TT-Cut II-M | TT-Cut II-M6 | TT-Cut II-M15 | TT-Cut II-T | |

| Max. X-Y feed speed (mm/min) | 6,000 | 6,000 | 15,000 | 6,000 |

| Main spindle taper | BT-20 | - | ISO 10 | BT-20 |

| Collet | ER16 | PC collet ø6 | SK-6 | ER16 |

| Main spindle (RPM) | 5,000 | 21,000 RPM | 5,000 | |

| Main spindle motor | AC Servo 750W | High spindle motor 750W | AC Servo 750W | |

| ATC (Auto Tool Change) | - | 5 tools, Z sensor | - | |

| Controller | PC-NC | Motion control | ||

| Feed distance (mm) | 225x95x145 | |||

| Machining range (mm) | 225x95x145 | |||

| X-Y table size (mm) | 350x150 | |||

| Feed method | Dovetail guide, ball screw | |||

| Feed motor | AC Servo | |||

| Operation method | Touch screen / MPG | |||

| Repetition accuracy (mm) | 0.005 | |||

| Position accuracy (mm) | 0.01 | |||

| Power | 110/220V Single phase(50/60Hz), 1.5kW | |||

| Machine dimensions | 820x800x1600 mm(with table) | |||

| Machine weight | Approx. 250kg(with table) | |||

| Standard accessories | MPG, PC, Machine table, Z-sensor, Coolant provider | MPG, PC, Machine table, Coolant provider | MPG, PC, Machine table, Z-sensor, Coolant provider | |